This blog post is brought to you by the RSAW experts in motor repair, sales, storage, and field service.

For the most accurate and up-to-date information, all our posts go through a rigorous review process by RSAW's leadership team.

It is that time of year again. Summer is here, and the temperatures are soaring. But unfortunately for your business it doesn’t stop there.

As the ambient temperature rises, the operating temperatures of your electric motors also increase.

Inevitably, someone will take note of the increased operating temperature during a maintenance activity or periodic inspection, at which point the question suddenly becomes:

At what point is the motor exceeding its design operating temperature?

Today’s article is intended to provide some practical information concerning motor operating temperatures.

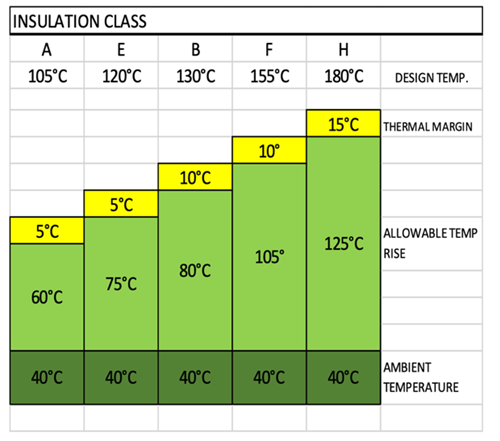

Most electric motors used in industrial settings are Class B or Class F designs. So, what happens if we operate a motor above its design temperature?

A general rule of thumb to consider is that for every 10°C above design temperature, the life of the insulation system is cut in half.

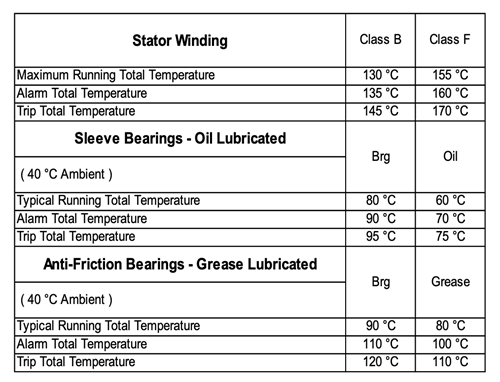

Motors are commonly equipped with protective devices (typically thermal cut-out devices on smaller low voltage motors <600v) or temperature sensors (typically rtd’s on medium and high voltage motors).

You should utilize these devices to track operating temperatures (rtd’s) and actively employ them as thermal overload protection (rtd’s and thermal cut-out devices).

If you find that you are exceeding one or more of these recommended temperature ranges you might ask yourself…

Answers can include but are not limited to:

The above information is intended to give you a general idea of motor operating temperatures for comparison purposes. For information specific to a particular machine, contact the original equipment manufacturer.

And if you are in need of periodic maintenance, inspection or repair to ensure that your motors are operating at proper temperatures, Contact Us today.